Let’s clear something up upfront: manufacturing software development isn’t “boring backend stuff.” In 2026, it’s the difference between factories that scale and factories that stall.

Modern manufacturing runs on software. It connects machines, people, and data in real time. It reduces downtime, predicts failures before they happen, and turns messy shop-floor operations into repeatable, measurable systems. Without it, you’re guessing. With it, you’re competing.

But building manufacturing software isn’t as simple as shipping another SaaS app. You’re dealing with legacy machines, real-time data, zero-tolerance downtime, strict security requirements, and teams that can’t afford bugs during a production run.

This guide cuts straight to what matters. You’ll learn what manufacturing software really includes in 2026, which features are non-negotiable, the trends actually shaping factories right now (not hype), and how to build systems that survive real-world production environments. No fluff. No theory. Just what works.

What Is Manufacturing Software Development?

Manufacturing software development is the process of building digital systems that run, optimize, and scale factory operations. These tools help manufacturers plan production, automate workflows, monitor equipment, and turn raw shop-floor data into decisions that actually improve output.

This isn’t generic business software. Manufacturing systems are designed to work with machines, sensors, operators, and legacy infrastructure, often in real time. That includes everything from production scheduling and inventory control to quality management, plant analytics, and predictive maintenance powered by AI.

In 2026, manufacturing software has moved far beyond spreadsheets and siloed systems. Modern platforms are cloud-connected, IoT-driven, and tightly integrated with on-site hardware. The end goal is straightforward: fewer breakdowns, improved visibility, safer operations, and higher margins without compromising production efficiency.

Why Manufacturing Software Matters in 2026

Manufacturing today isn’t about scale alone. It’s about speed, accuracy, and the ability to adapt when things break because they will. Software is what turns those challenges into manageable variables instead of costly surprises.

Here’s why manufacturing software is mission-critical in 2026:

- Supply chains are volatile by default: Modern software gives you real-time visibility across suppliers, inventory, and production, so disruptions don’t blindside your operations.

- Customers demand faster turnaround with zero tolerance for defects: Automation, analytics, and connected systems help you increase throughput while maintaining consistent quality.

- Regulatory pressure keeps rising: From traceability to reporting, the right software bakes compliance into your workflows instead of turning it into manual overhead.

Bottom line: factories still running on spreadsheets, paper, or patched-together legacy tools are paying a hidden tax of lost efficiency, higher risk, and slower growth. Modern manufacturing software removes that drag and turns operations into a competitive advantage.

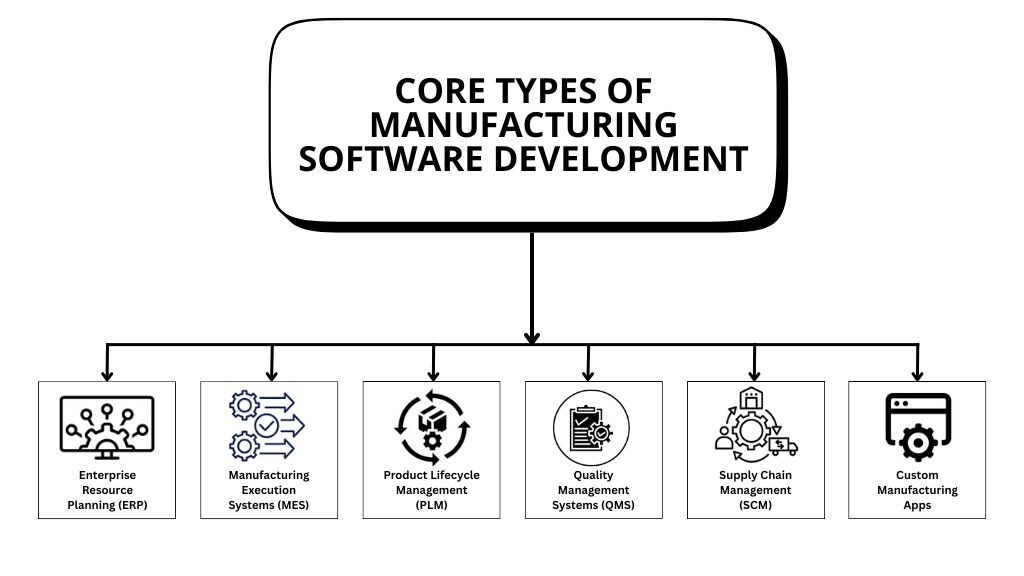

Core Types of Manufacturing Software (And What They Actually Do)

In 2026, modern factories don’t run on one piece of software. They run on a coordinated set of systems, each handling a different layer of planning, production, quality, and supply chain execution.

Enterprise Resource Planning (ERP)

Enterprise resource planning systems run the business side of manufacturing. They unify inventory, procurement, finance, and sales into a single system that connects directly to production data. In 2026, modern ERPs are cloud-native, modular, and built to integrate seamlessly with MES, IoT platforms, and analytics tools.

Manufacturing Execution Systems (MES)

MES software controls what happens on the shop floor. It tracks work in progress, monitors equipment performance, and ensures production matches the plan. Today’s MES platforms use real-time data and AI to surface bottlenecks and optimize throughput without slowing operations.

Product Lifecycle Management (PLM)

PLM software governs the design, engineering, production, and maintenance of products over time. It provides a structured way to manage product data, revisions, and collaboration across teams. By 2026, PLM is essential for handling complex products, faster iteration cycles, and regulatory requirements.

Quality Management Systems (QMS)

QMS platforms ensure that quality is built into manufacturing processes rather than inspected at the end. They standardize quality controls, manage compliance, and support continuous improvement initiatives. In today’s environment, QMS plays a central role in reducing risk and protecting brand reputation.

Supply Chain Management (SCM)

SCM software oversees the flow of materials, information, and products across the supply network. It helps manufacturers plan demand, source materials, manage logistics, and respond to disruptions. In 2026, SCM is a strategic function that focuses on both resilience and cost efficiency.

Custom Manufacturing Apps

Custom manufacturing software is built to address unique operational needs that standard platforms cannot fully support. It enables manufacturers to adapt technology to their processes rather than changing processes to fit the software. For many factories, custom systems are what turn digital tools into a real competitive advantage.

Key Features of Modern Manufacturing Software

Modern factories don’t need more software; they need the right capabilities built in by default. These features define what “production-ready” manufacturing software looks like in 2026:

- Real-time data visibility: Live insights from machines, sensors, and operators, so issues are spotted and fixed before they turn into downtime.

- Cloud-native architecture: Always-on access, easier scaling, faster updates, and lower infrastructure overhead across plants.

- Mobile-first access: Supervisors and technicians can monitor operations, log issues, and act immediately from any device.

- IoT and machine integration: Direct connectivity with equipment for health monitoring, inventory tracking, and automated maintenance.

- AI-powered analytics: Predicts failures, flags bottlenecks, and turns raw data into clear operational recommendations.

- Custom dashboards: Role-based views that surface the KPIs each team actually needs.

- Built-in security and compliance: Encryption, access controls, and audit-ready reporting by default.

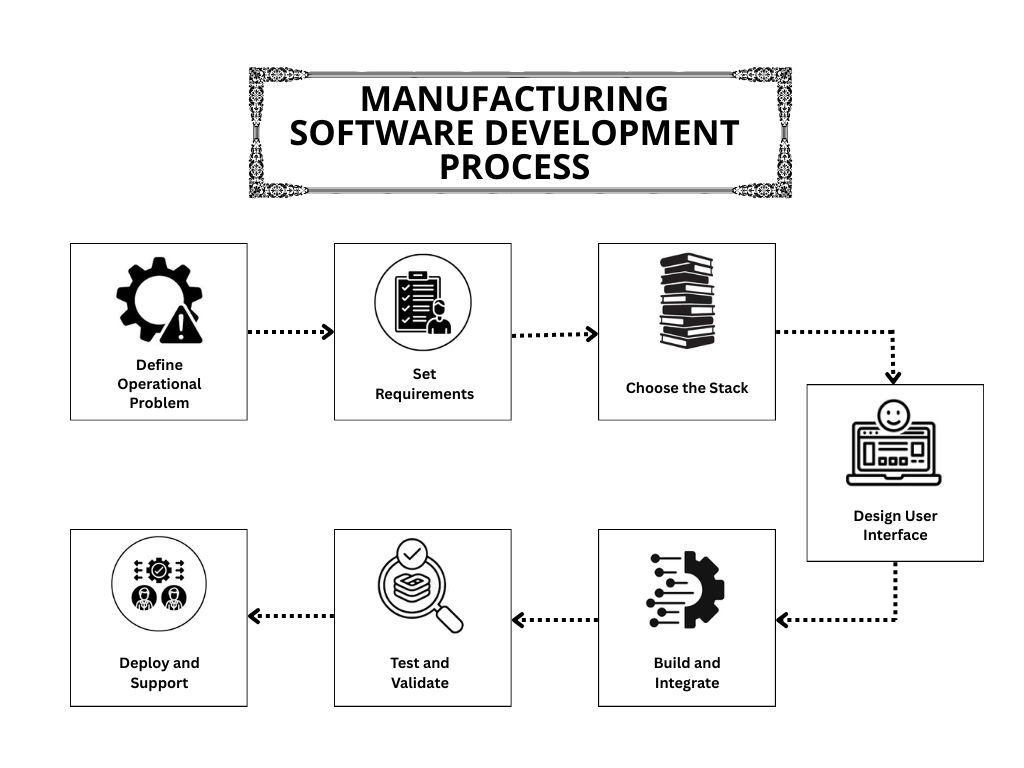

Manufacturing Software Development Process: Step by Step

Manufacturing software is won or lost before coding begins. In 2026, the best teams approach it as operational transformation, not IT. These steps reflect how software succeeds on real shop floors, not in demos:

Step 1: Define the Operational Problem

Every manufacturing environment has constraints that software must respect. This step focuses on understanding production goals, operational bottlenecks, downtime patterns, and compliance obligations. Input from operators, supervisors, engineers, and leadership is critical to avoid solving the wrong problem. Clear success metrics are established so impact can be measured after deployment.

Step 2: Set Requirements

Operational workflows are converted into functional and technical requirements that software teams can act on. This includes defining data sources, system integrations, performance expectations, and security needs. In 2026, requirements also account for usability, training effort, and adoption risk. The goal is to ensure the system fits how work is actually done.

Step 3: Choose the Stack

The technology stack determines how long the software remains useful. Modern manufacturing systems rely on cloud-native infrastructure, modular components, and API-driven integration. Choices are made to support future expansion, advanced analytics, and AI without re-architecting the platform. Flexibility is prioritized over short-term convenience.

Step 4: Design the User Interface

Manufacturing users operate under time and safety constraints. Interfaces are designed to surface critical information quickly and reduce unnecessary steps. Prototypes are tested with real users to ensure clarity, speed, and minimal training requirements. Good design directly impacts productivity and error rates on the shop floor.

Step 5: Build and Integrate

Development begins with essential workflows that support daily operations. The system is then integrated with machines, sensors, ERP, and other enterprise platforms. Open standards and secure APIs ensure consistent data flow across systems. Security and reliability are treated as foundational, not add-ons.

Step 6: Test and Validate

Testing goes beyond functionality and focuses on reliability, performance, and resilience. Software is validated using real data volumes and operating scenarios. Feedback from actual users helps identify usability gaps and operational risks early. This step significantly reduces post-launch disruptions.

Step 7: Deploy and Support

Deployment is staged to minimize risk and disruption to production. Training, monitoring, and feedback loops are established from day one. In 2026, manufacturing software is continuously improved as processes, volumes, and regulations evolve. Long-term support is built into the strategy, not treated as an afterthought.

Common Challenges in Manufacturing Software Development (2026)

Building software for the factory floor comes with constraints most SaaS teams never face. These challenges show up repeatedly in real-world manufacturing projects in 2026:

- Legacy equipment integration: Older machines weren’t built for connectivity. Bridging the gap often requires gateways, added sensors, or custom interfaces.

- Data silos: Disconnected systems limit visibility and slow decisions. Solving this means standardizing data flows and choosing platforms with open APIs.

- User adoption: Powerful software fails if teams don’t use it. Simple interfaces, hands-on training, and clear value to operators drive adoption.

- Security exposure: Connected factories increase attack surfaces. Strong access controls, encryption, and regular audits are now baseline requirements.

- Budget and timeline creep: Custom builds are easy to underestimate. Phased delivery, realistic scope, and frequent reviews keep projects on track.

Trends Shaping Manufacturing Software in 2026

Manufacturing software evolves as fast as the factories it supports. In 2026, the biggest shifts are focused on resilience, speed, and smarter decision-making at the edge, not experimental tech.

- AI-driven predictive maintenance: Failure prediction is now expected, not optional, helping reduce downtime and maintenance costs.

- Digital twins: Virtual factory models are used to test changes, simulate production, and troubleshoot without disrupting operations.

- Edge computing: Data is processed closer to machines to reduce latency, improve reliability, and keep sensitive data on-site.

- Low-code and no-code tools: Teams automate simple workflows quickly without relying entirely on developers.

- Sustainability-focused software: Platforms track energy use, emissions, and waste as part of daily operations.

- Security by default: Advanced authentication, segmentation, and real-time threat detection are built in from day one.

How Much Does Manufacturing Software Development Cost?

Costs vary widely depending on scope, customization, integrations, and the scale of deployment. Here’s a practical breakdown of what manufacturers are paying in 2026:

- Off-the-shelf software: Typically priced per user or per machine, with monthly costs ranging from $50–$500. Fast to deploy, lower upfront cost, but limited flexibility.

- Custom development: Starts around $75,000 for basic systems and can exceed $500,000 for large-scale platforms with IoT, AI, and enterprise integrations.

- Hidden and ongoing costs: Hardware upgrades, training, support, and rollout downtime add up. Most teams budget an extra 15–25% to avoid surprises.

How to Choose a Manufacturing Software Development Partner

Choosing a manufacturing software development partner is a strategic decision, not a procurement task. The right team accelerates digital transformation; the wrong one creates operational risk. In 2026, the gap between the two is wider than ever.

Industry-Specific Experience

Manufacturing environments come with constraints most software teams never face. A strong partner understands shop-floor operations, production pressure, regulatory requirements, and legacy infrastructure. This experience helps translate real operational problems into practical software solutions without disrupting production or overengineering the system.

Technical Depth and Decision-Making

In 2026, technical skill is about judgment as much as tools. Your partner should be fluent in cloud platforms, IoT, data engineering, AI, and cybersecurity, but also know when simplicity is the better choice. Clear explanations and proven architecture decisions matter more than buzzwords.

Integration and Interoperability

Modern factories run on a mix of old and new systems. The right partner knows how to connect machines, enterprise platforms, and third-party tools reliably. Strong integration capability ensures consistent data flow, minimal downtime, and long-term scalability.

Support and Maintenance

Manufacturing software must evolve alongside production, regulations, and business growth. A dependable partner plans for maintenance, performance tuning, security updates, and system scalability from the start. In 2026, long-term ownership ensures software remains reliable instead of becoming a liability.

Agile and Adaptive Delivery

Manufacturing environments are dynamic, and requirements often change mid-project. Agile delivery allows teams to release functionality in controlled stages, validate it on the shop floor, and adjust based on real feedback. In 2026, the best partners combine agility with operational discipline, balancing speed with reliability. This ensures software adapts to shifting priorities without introducing risk or disrupting production schedules.

Manufacturing Software Development Best Practices for 2026

Building manufacturing software is less about speed and more about durability. In 2026, the best systems are designed to survive real-world production pressure, evolving requirements, and long-term scale, not just pass initial demos.

Involve End Users Early

The people who run the shop floor understand constraints better than any spec document. Involving operators, supervisors, and managers early helps surface usability issues before they become expensive fixes. Early feedback also drives adoption once the system goes live.

Focus on Scalability

Factories don’t stand still, and software shouldn’t either. Systems should be built with modular architectures that allow features, plants, or data volumes to scale without rewrites. Cloud-native designs make growth predictable instead of painful.

Prioritize Security

Connected factories expand the attack surface. Security must be embedded into architecture, development, and deployment, not bolted on later. Regular audits, access controls, and patching are baseline expectations in 2026.

Document for Longevity

Good documentation protects software long after the original team moves on. Clear technical docs and user guides simplify onboarding, troubleshooting, and future enhancements. Documentation reduces risk and long-term maintenance costs.

Automate High-Friction Processes

Manual processes slow production and introduce avoidable errors. In 2026, manufacturing software should automate repetitive, rule-based tasks such as data collection, reporting, alerts, and routine approvals. The goal isn’t automation for its own sake, but freeing skilled teams to focus on decision-making, optimization, and continuous improvement.

Test in Real Production Conditions

Manufacturing software must prove itself where it will actually run. Testing should include real equipment, real data volumes, and real operator workflows under normal and peak conditions. In 2026, this step is critical for validating reliability, performance, and usability before rolling out across plants.

Manufacturing Software in Action: Real-World Cases (2026)

Abstract benefits are easy to promise. Real results are harder and more useful. These examples show how manufacturing software delivers measurable impact on the factory floor in 2026:

Case 1: Smart Scheduling Reduces Downtime

A mid-sized automotive components manufacturer deployed an MES with real-time scheduling logic. The system tracked machine availability, operator skills, and order priorities continuously. Production schedules adjusted automatically as conditions changed. Within six months, unplanned downtime dropped by roughly 30%, improving throughput without adding new equipment.

Case 2: Predictive Maintenance Cuts Operating Costs

A food processing facility implemented AI-driven predictive maintenance using connected sensors. Equipment health data was analyzed continuously to flag failure risks early. Maintenance teams shifted from reactive fixes to planned interventions. The result was fewer breakdowns, smoother operations, and annual savings of over $200,000 in avoided repairs and downtime.

Case 3: Digital Quality Management Improves Compliance

An electronics manufacturer replaced fragmented, paper-based quality checks with a centralized digital QMS. Quality data was captured automatically across production stages and analyzed in real time. This improved traceability, surfaced defects earlier in the process, and simplified regulatory reporting. As a result, audit preparation time was cut in half, recalls dropped, and overall product consistency improved across multiple product lines.

Building Smarter Factories in 2026

Manufacturing software is no longer a “digital upgrade.” In 2026, it’s a core operational asset that determines how efficiently factories run, how quickly they adapt, and how resilient they are under pressure. The gap between software-driven plants and everyone else keeps widening.

The winning approach is straightforward: solve a real operational problem, build on flexible technology, and design for the people who run the floor every day. When software delivers clear visibility, proactive maintenance, and reliable execution, efficiency follows.

The factories pulling ahead aren’t the largest or the most automated; they’re the ones making smarter decisions, faster. If manufacturing software is on your roadmap, the best time to act isn’t “next year.” It’s now before inefficiency becomes your competitive disadvantage.